Aluminum Holders

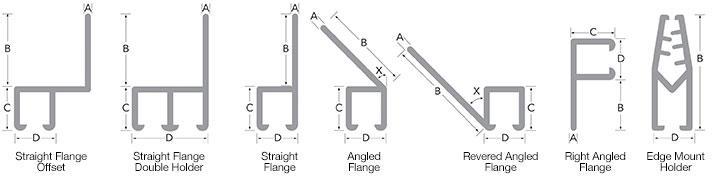

SEALEZE® aluminum brush holders are designed to fit our straight strip brushes and are available in 8-foot or 10-foot lengths. Stock brush holders have a clear anodized finish, without mounting holes. To select the correct size, match the section letter of the brush to the section letter of the holder and then choose the flange angle needed. Brush holders can be cut to length, provided with punched holes or machined slots for easy mounting. Click here for standard mounting hole options.

Available stock finishes include mill, clear anodized, black anodized, gold anodized, and dark brown.

Holders can be formed into custom shapes to match custom-formed brush. For assistance in selecting the right holder and mounting configuration for your application, contact a SEALEZE® Sales Representative.

Plastic Edge Mount Holders

Especially designed to use on metal furniture cabinets, SEALEZE® edge mount holders are easily installed. No tools are necesary. Our edge mount holders easliy attach brush to furniture cabinets, allowing cables to pass through while minimizing dust, dirt and debris.

Made of PVC plastic, SEALEZE® edge mount holders are durable, resistant to UV degredation and won't rust or corrode. Holders are made to accomodate SEALEZE® size C or D strip brush to meet your applicaitons needs.

To email us your application information, click here. Or, call 1-800-787-7325.

| SEALEZE® Stock Holders | |||||||

|---|---|---|---|---|---|---|---|

| Fits Brush Section Size | Holder Product Code | Flange Type | X | A | B | C | D |

| A | XTJ140CLA | Angled | 40° | 0.062 | 0.750 | 0.225 | 0.213 |

| A | XTA190CLA | Right Angled | 90° | 0.056 | 0.347 | 0.204 | 0.220 |

| A | XTA180CLA | Straight | 180° | 0.040 | 0.446 | 0.212 | 0.197 |

| B | XTB215CLA | Angled | 15° | 0.062 | 0.768 | 0.265 | 0.262 |

| B | XTB230CLA | Angled | 30° | 0.062 | 0.862 | 0.265 | 0.262 |

| B | XTB290CLA | Right Angled | 90° | 0.055 | 0.423 | 0.266 | 0.264 |

| B | XTB292CLA | Right Angled | 90° | 0.055 | 1.250 | 0.266 | 0.264 |

| B | XTB280CLA | Straight | 180° | 0.062 | 0.427 | 0.264 | 0.267 |

| B | XTB210CLA | Straight | 180° | 0.062 | 0.735 | 0.265 | 0.262 |

| C* | XTC345CLA | Angled | 45° | 0.050 | 1.250 | 0.311 | 0.292 |

| C* | XTC390CLA | Right Angled | 90° | 0.060 | 0.663 | 0.303 | 0.331 |

| C* | XTC380CLA | Straight | 180° | 0.050 | 0.439 | 0.311 | 0.292 |

| C* | XTC381CLA | Straight | 180° | 0.050 | 0.750 | 0.311 | 0.292 |

| C* | XTC382CLA | Straight | 180° | 0.050 | 1.500 | 0.311 | 0.292 |

| C* | XTCEMPBK | Edge Mount | 180° | N/A | 0.960 | N/A | 0.280 |

| C* | XTC383CLA | Straight | 180° | 0.055 | 3.000 | 0.311 | 0.292 |

| D* | XTD445CLA | Angled | 45° | 0.062 | 0.844 | 0.391 | 0.366 |

| D* | XTD45XCLA | Angled | 45° | 0.062 | 1.890 | 0.391 | 0.366 |

| D* | XTD45RCLA (Reverse Flange) | Angled | 45° | 0.062 | 1.000 | 0.391 | 0.366 |

| D* | XTD490CLA | Right Angled | 90° | 0.062 | 0.697 | 0.365 | 0.391 |

| D* | XTD480CLA | Straight | 180° | 0.062 | 0.711 | 0.391 | 0.366 |

| D* | XTD482CLA | Straight | 180° | 0.062 | 1.500 | 0.391 | 0.366 |

| D* | XTD483CLA | Straight | 180° | 0.062 | 3.000 | 0.391 | 0.366 |

| D* | XTDEMPBK | Edge Mount | 180° | N/A | 0.960 | N/A | 0.340 |

| F | XTF580CLA | Straight | 180° | 0.062 | 1.000 | 0.474 | 0.469 |

| F | XTF582CLA | Straight | 180° | 0.062 | 1.500 | 0.474 | 0.469 |

| F | XTF545CLA | Angled | 45° | 0.062 | 1.500 | 0.474 | 0.469 |

| F | XTF590CLA | Right Angled | 90° | 0.062 | 1.000 | 0.469 | 0.474 |

| G | XTG645CLA | Angled | 45° | 0.062 | 1.000 | 0.528 | 0.505 |

| G | XTG690CLA | Right Angled | 90° | 0.062 | 0.873 | 0.505 | 0.528 |

| G | XTG680CLA ( Also available in polypropylene and stainless steel.) | Straight | 180° | 0.062 | 0.784 | 0.528 | 0.505 |

| G | XTG682CLA | Straight | 180° | 0.062 | 1.472 | 0.528 | 0.505 |

| G | XTG685CLA | Straight | 180° | 0.079 | 4.894 | 0.576 | 0.539 |

| G | XTGG680CLA (double) | Straight | 180° | 0.062 | 1.250 | 0.528 | 0.948 |

| G | XTGHDGG80ML-114 (double)† | Straight | 180° | 0.090 | 1.78 | 0.596 | 1.032 |

| K | XTK1092CLA | Right Angled | 90° | 0.079 | 1.751 | 0.667 | 0.688 |

| K | XTK1082CLA | Straight | 180° | 0.079 | 2.001 | 0.689 | 0.667 |

*Can be used with Ez-Flex flexible backed strip brush.

† Specifically designed for G brush with long OATS.

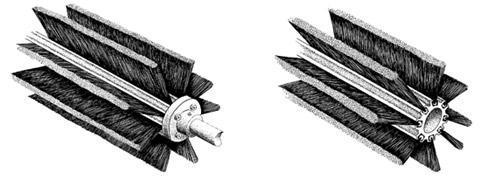

Rotary Brushes

Custom rotary strip brushes are available in two sizes: D Series and G Series. Extrusions are made from aluminum alloy. Machined aluminum alloy mounting hubs are available. Hubs for D Series rotary brushes enable mounting on shafts with 0.750 inch diameter; hubs for G Series rotary brushes enable mounting on shafts with 1.000 inch diameter. Brush channel materials include galvanized steel and T-304, T-304L, T-316 and T-316L stainless steels. A wide variety of filament materials is available (including crimped and level) with a wide selection of filament diameters. Custom mandrels and hubs can be designed and manufactured, upon request.

SEALEZE® rotary strip brushes are designed for low-RPM applications, typically less than 100 RPM.

If your application requires rotary strip brushes with special requirements, contact a SEALEZE® Sales Representative for more information.

| Rotary Strip Brush Assemblies | |||

|---|---|---|---|

| Extrusion Dimensions | Minimum Assembly with Brush | ||

| OD | ID | OD | |

| Series D | 2.220 | 1.125 | 3.18 |

| Series G | 2.743 | 1.375 | 4.25 |

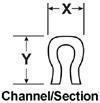

| Channel Section Size | |||

| Section Size | (X) Width (inches) | (Y) Height (inches) |  |

| D | 0.240 | 0.256 | |

| G | 0.350 | 0.370 | |

Download a worksheet for Series D Rotary Brushes, worksheet for Series G Rotary Brushes or, go to the online Rotary Strip Brush worksheet.